Water injection means that some illegal operators of meat foods artificially inject water of various water quality into the livestock body before slaughter of livestock: clean water, salt water or even industrial sewage, or add water to the meat after slaughter to increase the meat weight. The purpose of seeking profits. The harm caused by water injection has been repeatedly emphasized by relevant departments. The people have a certain understanding and understanding of the harm caused by water injection. However, the incidents of water injection and meat incidents still appear in various media and news from time to time, which make the general public unpredictable. Even hear the "water injection" and change color. Well, we have to conduct a thorough discussion and reflection on how we should judge the problems of water injection and water injection.

How to determine the water injection:

1. Observing the flesh: If slaughtered animals are carried out in the normal way, the meat of the slaughtered livestock is dark red and has a certain degree of elasticity. When the meat of the livestock is pressed by hand, the pressing part will soon recover, and no water will seep out. The meat after the water injection is white, and the liquid will leak when pressed by hand.

2. Observe the section of livestock meat: When the meat is cut with a knife, if there is no water leakage, and the cut surface is smooth, it indicates that the meat has not been filled with water; on the contrary, if there is a light red juice out of the cut surface, water injection can be confirmed.

3. Test paper to check the injection of water: Cut out a 10 x 1 cm test paper and insert it into the incision of the meat to be examined. Then, after about 1 minute, the test strips were removed to observe the degree of infiltration, adhesion, and tension of the paper. If the infiltrated part is More than 2cm, or if the adhesive force is poor, the test paper will be broken as soon as it is pulled, which means that the meat is injected with water.

4. Magnifying glass to check the water injection: Observe the muscle tissue of the meat to be examined with a low power magnifying glass. If the muscle fiber of the meat to be tested is swollen and disordered, there is a break, the color is pale, and there is a lot of moisture and exudative substances, the test object can be determined. For water injection.

5. The most practical method, but also the simplest - sniffing. When we sniff the meat to be tested with the nose, half of the carcasses will have a fresh taste, while the water-injected meat will have an odor, and even foul odors.

Water injection type:

The injected meat includes water-fed beef, water-injected lamb, water-injected pork, and water-injected white poultry meat.

Water-fed beef: After the water injection, the beef's elasticity is reduced, the meat is soft, the meat quality is bad, the viscosity is decreased, and water seeps out.

Water-injected mutton: After the injection of water, the mutton section is moist and even water flows out; the elasticity of the meat is not good, and it is difficult to restore the original state after pressing.

Water injection of white poultry: The most frequent is to inject water into the abdomen or leg base of the animal, chest

The most common is to inject water under the abdomen or leg heel, chest muscles and subcutaneous. Poor water injection

About 20% of body weight, the appearance of the skin appears to be tense and flat, the pores become thick and shallow, and the bleeding skin is broken with the tip of the skin, and the muscle color becomes pale and pale. In winter, the knife is cut, the knife marks are hard, the cut surface has ice slag, the blood vessels are thick, and muscles and blood vessels have small ice cubes.

Water-injected pork: After the hog carcass is cut, the muscles appear pale in appearance, and the meat is soft and juicy.

Lack of elasticity and sheen.

Water hazards:

1. The most obvious hazard of waterflood is the loss of meat quality. After the water is injected into the meat, it may cause the somatic cells of the meat to rupture, causing the loss of protein and reducing the nutrients of the meat. At the same time, the biochemical internal environment and the enzyme biochemical system in meat juice suffer from various degrees of damage, making the meat easily degenerate and difficult to store.

2. Because the injected water is generally unclean, it contains a lot of microbial bacteria. When microorganisms reproduce by themselves, they will produce a large number of bacterial viruses, which will cause fresh meat to be infected by viruses. The taste and nutritional value of pork, beef, and mutton that are filled with water will be greatly reduced, and they will even be detrimental to the body.

3. If the injected water is industrial wastewater or domestic sewage, the impact is even greater. This water is injected into the animal and absorbed directly by the body. If the waste water contains toxic substances, it enters the body after being eaten by the human body. If the contaminant content is not high, it may get sick within a few months; if the contaminant content is high, then it is possible to get sick immediately. And some substances will make the gene mutation, affecting the normal growth and development of the next generation.

Therefore, it is recommended that consumers look at the color of the meat before eating meat, cut the meat, and then smell the flesh, can basically determine the meat is fresh or not, of course, this with the experience and people's sense organs are also certain Contact. The popularization of water-borne meat, on the one hand, is the non-standardization of the market. On the other hand, the deeper level is the quality of the people. It is unscrupulous to extract huge profits. We should actively resist this situation.

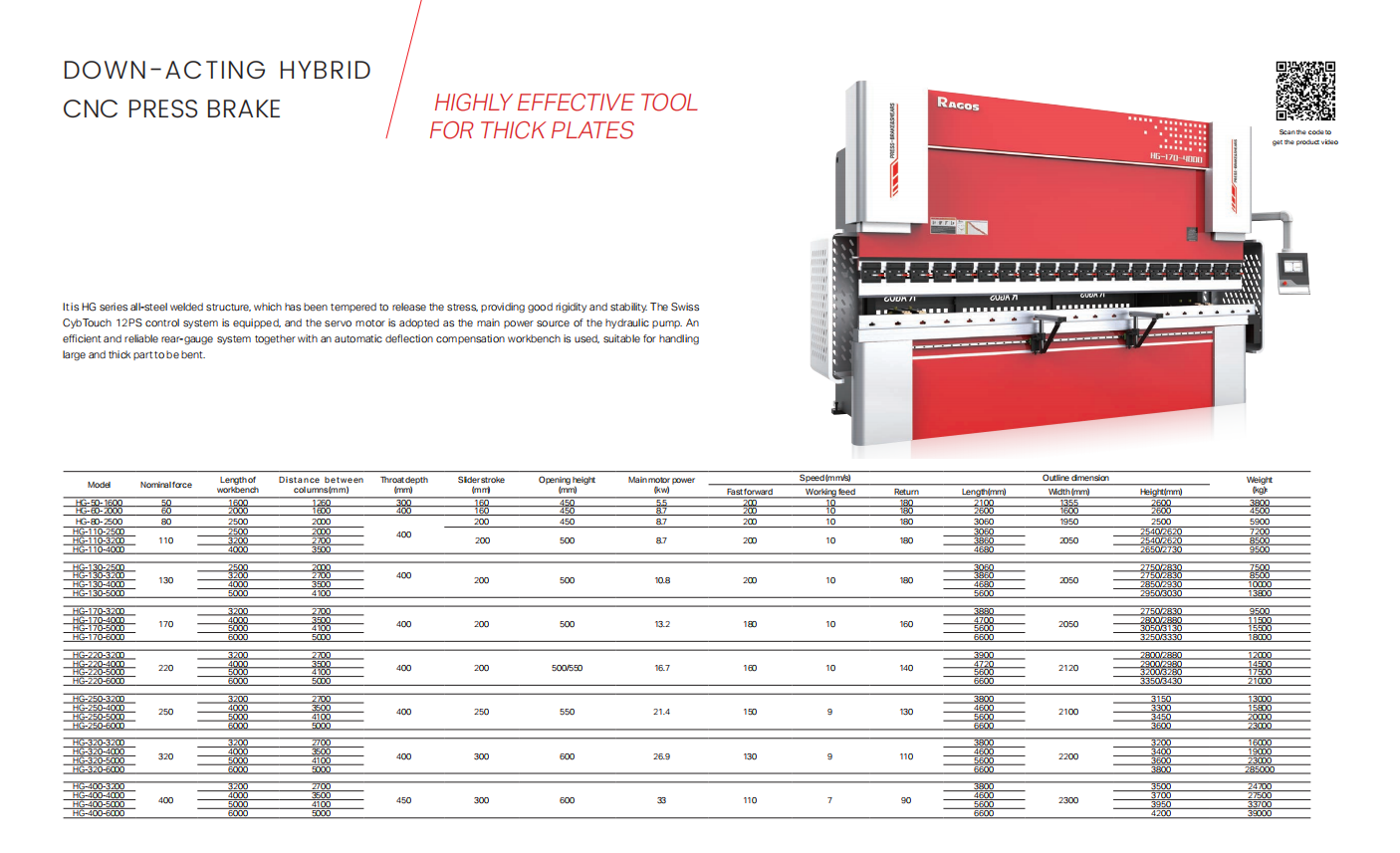

Dual servo hybrid CNC Press Brake

Features:

Introduction:

Features And Function

Fast - 10% performance increase by reducing cycle time

High efficiency - 50% increase in energy efficiency (compared to traditional systems)

Precise - positioning accuracy reaches 0.005mm

Features And Function

Fast - 10% performance increase by reducing cycle time

High efficiency - 50% increase in energy efficiency (compared to traditional systems)

Precise - positioning accuracy reaches 0.005mm

Reliable - minimal risk of leakage

Low Noise - Noise reduction in all operating modes

compact - creating new spaces on the midplane

Compatible - easy integration into CNC

Optimization - less installation and service fees

Environmental protection - the amount of hydraulic oil is greatly reduced

Down-acting press brake,sheet metal panel benders,cnc panel bender,Automatic Panel Bender,Sheet Metal Bending Center,ragos

FOSHAN RAGOS NC EQUIPMENT CO.,LTD. , https://www.ragosnc.com